Lambley Viaduct Spandrel Repair

The Project

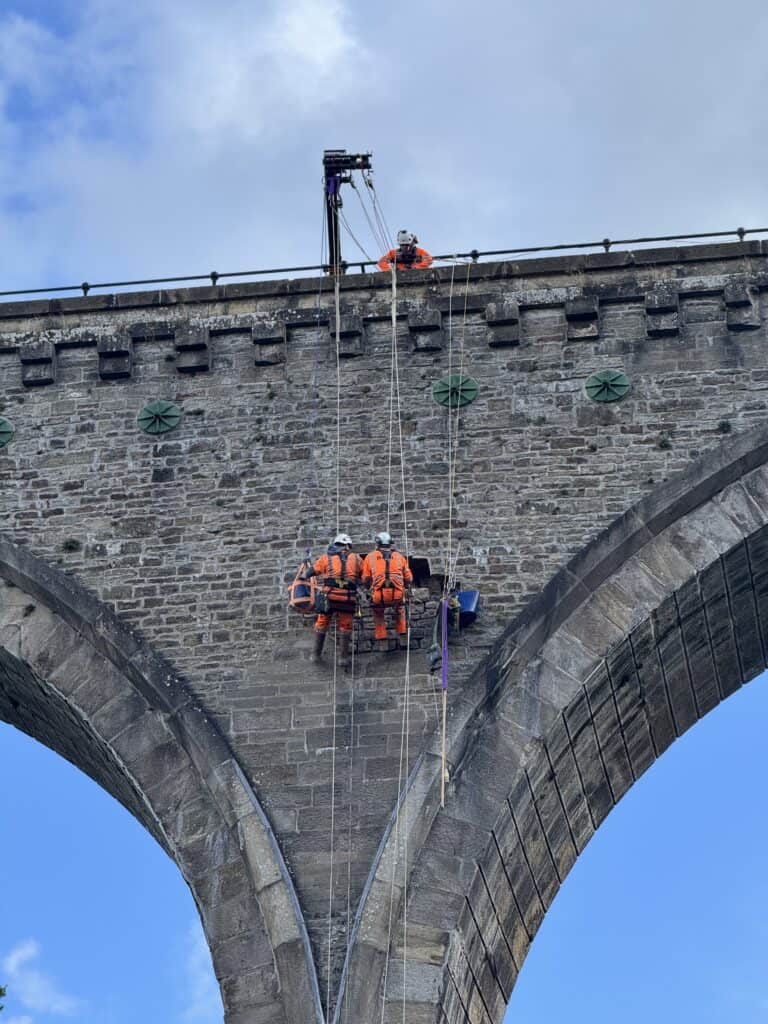

During the summer of 2025, a large section of stonework fell from a spandrel wall on the disused Lambley Viaduct near Haltwhistle in Northumberland. Lambley Viaduct is a Grade II* listed, 260 metre long Victorian viaduct built in 1852 for the Haltwhistle to Alston branch line in order to transport coal and lead from the mines at Alston to the rest of the world. It crosses the River South Tyne, with nine main 17 metre arches and a height of over 33 metres. Following closure of the railway in 1976, the viaduct fell into disrepair before undergoing significant repairs in the 1990s.

Having already worked with the South Tynedale Railway Preservation Society on other structures on the line, Bell Access were asked to assist with the repair of the missing stonework. On an initial site visit, it was decided that an inspection by the engineering architect firm Blackett-Ord was required. We returned to site a few weeks later, and used our JCB 514-40 micro tele-handler as a high anchor point for the rope system. Our Skylotec Actsafe ICX power ascender was utilised to safely lower the non-rope access engineer to the defect, and then smoothly raise them back up to the bridge deck.

We returned to site in September 2025 to carry out the remediation works after receiving drawings from the engineering architects. The challenges that we faced were limited access to the structure, with the nearest road access being 500 metres away; approximately 1 tonne of stone had fallen to the ground and would need to be recovered and reused; the historic listed structure meant that only lime mortar could be used for the repair.

Our Method

For the remediation works, we once again used the JCB tele-handler as an anchor point. The Actsafe power ascender was this time used to haul the fallen masonry from the ground to the bridge deck where it could be prepared for re-use in the repair. Using the power ascender we were able to safely lower stones and materials down to the repair. A strict exclusion zone with barriers and signage was established underneath the work area so that the technicians could safely place the stones without endangering the public. As often in the Northern Pennines, the weather was changeable during the works, which meant that our team used flexible working to get the repair completed on schedule.

Work Undertaken

- Light vegetation removal on old track to allow for 4×4 vehicle access to the structure

- Access provided for 3rd party engineering architect to defect

- 1 tonne of stone recovered from the base of the structure and hauled 30m to the bridge deck for re-use

- Old stone dressed and cleaned of lime mortar

- Approximately 1m2 of new matched stone added to repair

- 2.6m2 hole filled and rebuilt (pinned using stainless dowels where required)

- Further 1.5m2 area of bulging masonry removed and rebuilt

- Sole use of pure NHL3.5 lime mortar with a specific Cardew Mires local sand

- Pointing up of the repaired area

- Assist South Tynedale Railway with inspection and clearing of drainage on the deck

The Outcome

Using innovative Industrial Rope Access techniques, our team was able to deliver a massive time and cost saving over traditional scaffold access, whilst not compromising on quality or safety. Despite the challenges posed by the access and the Pennine weather, the works were completed on time, and on budget.

Project Details

Location: Lambley, Northumberland

Client: South Tynedale Railway Preservation Society

Duration: 2 weeks